- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

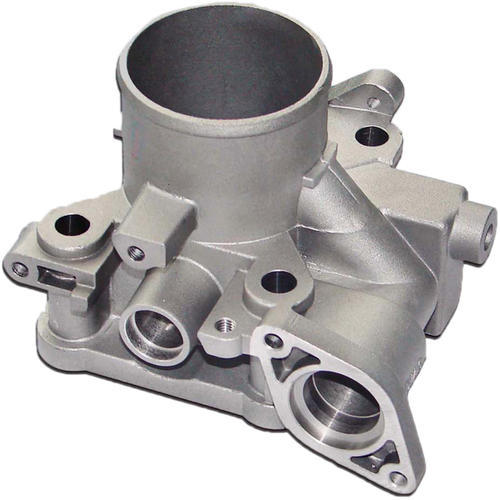

Experts Level Casting News

What is Investment Casting and How Does It Work?

Factors such as design requirements, cost, and feasibility to manufacture dictate which casting process is most suitable to manufacture a product. This article describing investment casting is intended to help you make an informed casting decision.

Read MoreHow to use Urea Core in Precision Casting

The characteristic of the urea core process is that a soluble urea core is used to compose the complex structure of the part's cavity, which is put into a profiling internal pressure wax for molding, and then the urea core is dissolved and lost in water at 25~30℃. After the wax model is made by this......

Read MoreLost Foam Casting

Lost foam casting is a process used to create complex metal pieces and parts in which molten metal evaporates a foam mold being held still with sand. The process starts with a polystyrene foam as the mold material which can be carved, machined from a foam block, or created using a process similar to......

Read MoreLost Wax Casting Guide

Lost wax casting, also known as “investment casting,” is the process by which a single metal object is cast from a wax model. It is a highly versatile process that achieves exceptionally detailed results. This guide will cover how to start lost wax casting and what you can create with the process.

Read More