- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Casting Process

Silica Sol Casting

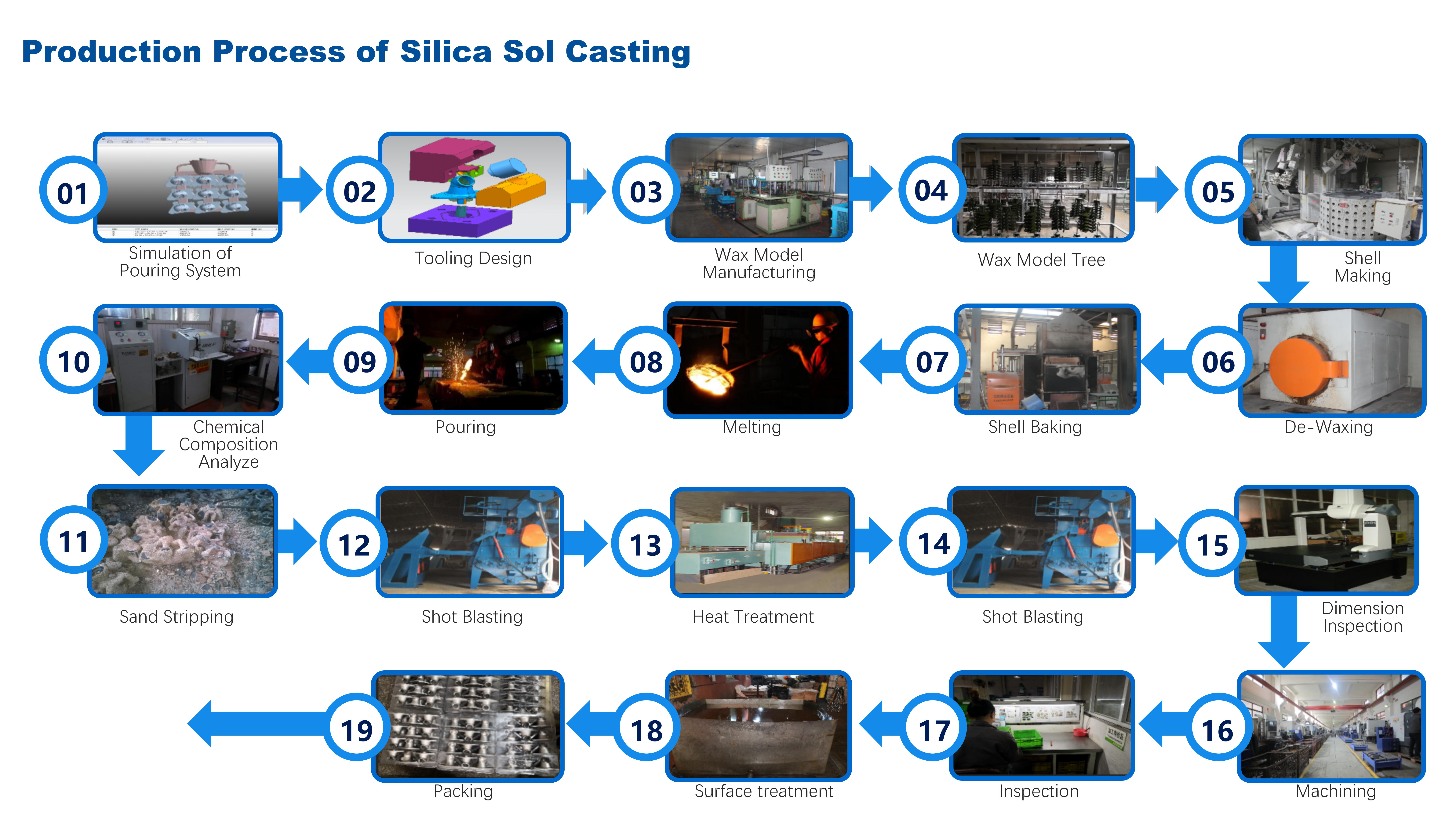

Silica Sol Investment Casting is a form of investment casting. The process is very similar except that the investment mould is made from silica sol zircon sand mixed with refractory powder. Silica sol zircon sand is exceptionally fine-grained (10-20 Microns) and can be mixed to a slurry with very low viscosity when creating the mould. The result is a casting method that delivers dimensionally accurate castings with excellent as-cast surface finishes. Crucially, the silica sol zircon mould can withstand temperatures up to 2000°C, making them very useful when casting high temperature alloy steels and stainless steels.

VIEW DETAILS

|

Process |

Silica sol Casting (Green Wax) |

|---|---|

|

Mold |

General Aluminum Mold & Steel Mold |

|

Mold Material |

Middle Temperature Wax |

|

Mold Shell |

Silica sol, Mullite Sand, Zircon Sand |

|

Technology Characteristics |

Suitable for producing small parts. Better precision. Better surface roughness. Can large extent reduce machining. |

|

Tolerance Range |

CT5 to CT6 |

|

Single Weight |

0.01kgs to 30kgs |

|

Surface Roughness |

RA6.3 |

|

Casting Material Type |

Carbon Steel, Alloy Steel, Stainless Steel, Ductile Iron. |

|

Common Material Specification |

GB, ASTM,SAE,AISI,DIN,BS,JIS,NF,EN,AAR,ISO |

|

Product application field |

Automobile, Engineering Machinery, Railway, Marine, Agricultural Machinery, Mining and other industrial fields |

|

Advantages& disadvantages |

Environmental protection, surface roughness is better than RA6.3, but the price is 1.0-2.0 yuan /KG higher than sodium silicate |