- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Experts Level Casting News

What are the basic requirements for the prevention of pitting on the surface of precision castings?

The quality of the materials used should be guaranteed, at least qualified materials should be used. Moreover, it should be carried out strictly in accordance with the process specifications and operating requirements, and there should be no wrong operation to avoid affecting the quality of the cast......

Read MoreApplication of Silica Sol Precision Casting and Precision Casting Heat Treatment Description

Precision casting is one of the casting methods, and it is also one of the keywords of the website, so it is very necessary to know and understand it so that you can get familiar with it, rather than knowing nothing about it. Moreover, this is also a very good learning opportunity for us to increase......

Read MoreCauses and solutions for pores in silica sol precision casting

Porosity is a common precision casting defect. Porosity refers to the smooth hole defect in individual positions of silica sol precision casting. Porosity is usually discovered after processing. Combined with years of workshop production experience, the causes and prevention methods of pores in prec......

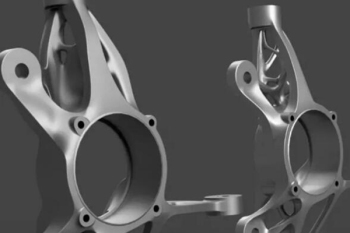

Read MoreWhat are the forging processes for auto parts forging?

Auto parts forging is a processing method that uses forging equipment to pressurize metal blanks, causing the auto parts blanks to undergo plastic deformation to obtain steel castings with certain physical properties, shapes and specifications. Forging (forging and forging) One of the major componen......

Read MoreIntroduction to Shell Mold Casting

Shell Mold Casting, also known as shell mold casting or coated sand casting, is a special casting process whose main feature is to form a thin shell mold by using a mixture of silica sand or zircon sand and resin or resin coated sand. The following is a detailed introduction to Shell Mold Casting:

Read More