- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Experts Level Casting News

How to deal with the deformation problem of precision castings

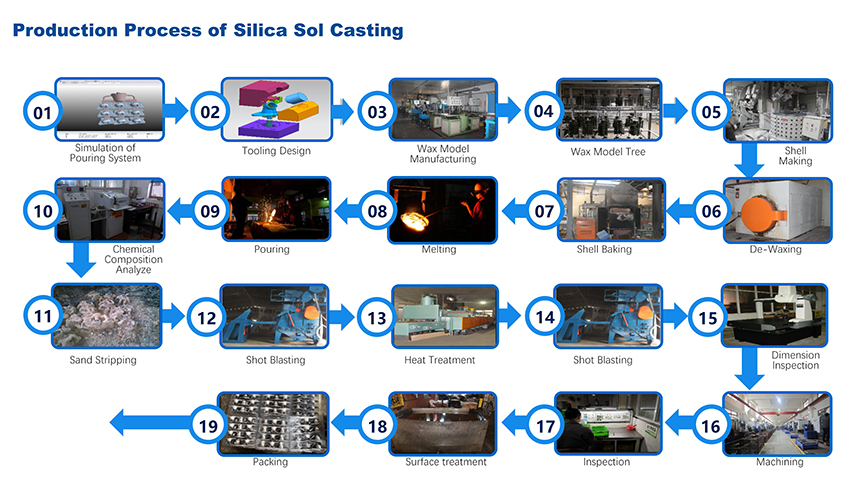

During the production process of precision castings, due to some hardware facilities, management, pouring cooling and correction problems, casting deformation will occur. How to choose a silica sol precision casting manufacturer? So how should we deal with casting deformation?

Read MoreWhy do precision castings need to be pickled?

Pickling of investment castings is generally a process in which castings are immersed in an acidic solution and used to remove various oxidized substances and rust on the steel surface through chemical reactions. If the pickling is done well, the next passivation process will be much simpler.

Read MoreAdvantages and Disadvantages of Stainless Steel Precision Casting Processing

Stainless steel precision casting is a process that uses wax mold → sand mold → liquid material filling and molding to produce such irregular-shaped products when it is impossible to produce stainless steel products by bending and other processes. So everyone knows what are the advantages and disadv......

Read MoreMethods for cleaning silica sol precision casting parts

Cleaning with clean water: Cleaning silica sol precision casting parts with clean water can remove impurities on the surface and residues adhered to the pollutant, but it cannot effectively remove some stains that are difficult to clean.

Read MoreMethods to protect silica sol precision cast parts

Use anti-rust agents: Silica sol precision casting parts should be treated with anti-rust agents during storage, which can effectively prevent them from getting damp and rusting. Generally speaking, the use of corresponding rust inhibitors can increase the service life of silica sol precision castin......

Read More