- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

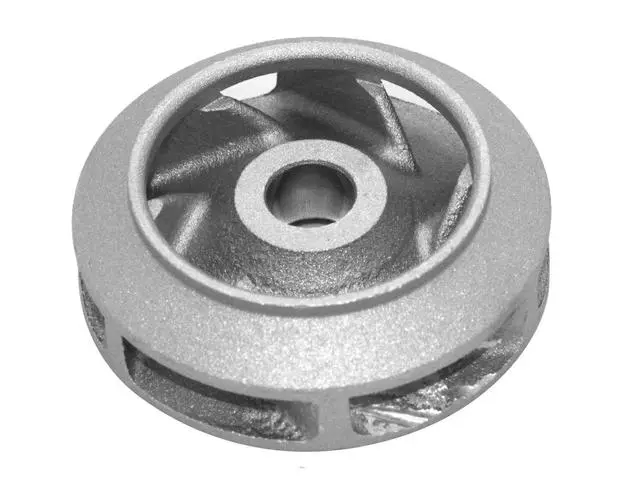

Silica Sol Investment Casting

Silica Sol Investment Casting

Why useSilica Sol Investment Casting?

Benefits ofsilica sol investment casting:

● Great versatility; suitable for casting most metals.

● Will allow very intricate castings to be produced with thin walls.

● Smooth surface finishes are possible with no parting line so machining and finishing are reduced or eliminated.

● Allows un-machinable parts to be cast accurately instead.

● Excellent dimensional accuracy Silica Sol Process 1.A metal die is made, the impression being the same as required in the final mould.

2.Molten wax is injected into the metal die to create a pattern, allowed to solidify and then removed. Some complex wax patterns are fabricated by joining several separate patterns together using an adhesive.

3.The waxes are then assembled on a wax tree, many parts can be put on the tree depending on size, it is common for components to be in the weight range 0.1kg up to 50kg.

4.The tree is then immersed in silica sol zircon slurry to coat the wax, the slurry is exceptionally fine with low viscosity resulting in an excellent as-cast surface finish. The slurry is coated with a refractory material and the process is repeated several times until a shell is created around the wax pattern.

5.The drying process is critical. The shells must be allowed to dry naturally in a constant temperature to allow the silica sol gels and refractory particles to bond, the result is a strong, high quality shell mould. The trees of wax are put into ovens of about 200 degrees to melt out the wax.

6.When all wax is removed the trees are heated up to over 1000 degrees to complete preparation for casting.

7.The metal is then poured into the hot mould, which allows the alloy to reach the thinnest sections of the mould before it solidifies.

| Process | Silica sol Casting (Green Wax) |

| Mold | General Aluminum Mold & Steel Mold |

| Mold Material | Middle Temperature Wax |

| Mold Shell | Silica sol, Mullite Sand, Zircon Sand |

| Technology Characteristics | Suitable for producing small parts. Better precision. Better surface roughness. Can large extent reduce machining. |

| Tolerance Range | CT5 to CT6 |

| Single Weight | 0.01kgs to 30kgs |

| Surface Roughness | RA6.3 |

| Casting Material Type | Carbon Steel, Alloy Steel, Stainless Steel, Ductile Iron. |

| Common Material Specification | GB, ASTM,SAE,AISI,DIN,BS,JIS,NF,EN,AAR,ISO |

| Product application field | Automobile, Engineering Machinery, Railway, Marine, Agricultural Machinery, Mining and other industrial fields |

| Advantages& disadvantages | Environmental protection, surface roughness is better than RA6.3, but the price is 1.0-2.0 yuan /KG higher than sodium silicate |

Lost Foam Casting

Lost Foam Casting

The foam pattern was first used in metalworking in 1958. Although this mold casting technique is not as popular as other methods such as sand mold casting or permanent casting, it maintains outstanding advantages, especially in casting complicated and precise molds.

Unlike traditional methods which include the pattern withdrawn process before casting and require skillfulness in the pattern removal step, with respect to the lost foam method, the pattern is evaporated when the molten metal is poured into helping to reduce these considerations.

Thelost foam castingprocess

Lost foam process

The lost foam casting technology included 5 steps: designing the pattern; applying insulation painting; placing the pattern into the sand flask; pouring the molten metal; and collecting the castings.

How a lost foam pattern is made?

Firstly, a pattern is designed from polystyrene foam. This type of foam plays an important role in this casting method. It is a good thermal insulator and chemical resistance, enable working normally at the temperature below 75 ℃.

Depending on difficulty and details of the product, the foam pattern can be made from different manners.

Making the pattern for lost foam process

For highly detailed casting patterns, the foam pattern is partly made and glued together. For the small volume, foundries often make patterns by hand-cut or machined from a solid foam block. If the pattern is simple enough, a hot wire foam cutter can be applied.

In case the volume is large, the pattern can be mass-produced by a process similar to injection molding.

Polystyrene beads are injected in a pre-heated aluminum mold at low pressure. After that steam is applied leading to polystyrene expands more to fill the empty cavity and then form the pattern or a section. The final pattern is approximately 97.5% air and 2.5% polystyrene.

Casting process

Once the pattern is formed, it is coated with insulation paint, placed in a flask and surrounded in un-bonded sand and compacted.

the pattern is coated with insulation paint in lost foam process

The covering paint works to increase the durability of the mold surface, protect from erosion, and broken. Whereas, the flask is designed suitably for this method so that when the molten metal is poured into the mold, the gas generated by foam burning is withdrawn completely.

After molten metal is poured into the foam pattern, the foam pattern is burned out and the casting is formed.

Lost foam method is applied to cast steel product

| Process | Lost Foam Casting |

| Pattern | General Aluminum mould & Steel mold |

| Mould Material | STMMA Copolymer Resin |

| Mould Shell | Fireproof Coating |

| Technology Characteristics | Instead of the traditional sand Mold casting. Without the core-making process. Better dimensional accuracy. |

| Tolerance Range | CT8 to CT9 |

| Single Weight | 0.2kgs to 200kgs |

| Surface Roughness | RA12.5 |

| Casting Material Type | Grey Iron and Ductile Iron, Alloy Steel |

| Common Material Specification | GB, ASTM,SAE,AISI,DIN,BS,JIS,NF,EN,AAR,ISO |

| Product application field | Automobile, Engineering Machinery, Railway, Marine, Agricultural Machinery, Mining and other industrial fields |

Shell Mold Casting

Shell Mold Casting

Shell mold castingallows the use of both ferrous and non-ferrous metals, most commonly using cast iron, carbon steel, alloy steel, stainless steel, aluminum alloys, and copper alloys. Typical parts are small-to-medium in size and require high accuracy, such as gear housings, cylinder heads, connecting rods, and lever arms.

Theshell mold castingprocess consists of the following steps:

1.Pattern creation - A two-piece metal pattern is created in the shape of the desired part, typically from iron or steel. Other materials are sometimes used, such as aluminum for low volume production or graphite for casting reactive materials.

2.Mold creation - First, each pattern half is heated to 175-370°C (350-700°F) and coated with a lubricant to facilitate removal. Next, the heated pattern is clamped to a dump box, which contains a mixture of sand and a resin binder. The dump box is inverted, allowing this sand-resin mixture to coat the pattern. The heated pattern partially cures the mixture, which now forms a shell around the pattern. Each pattern half and surrounding shell is cured to completion in an oven and then the shell is ejected from the pattern.

3.Mold assembly - The two shell halves are joined together and securely clamped to form the complete shell mold. If any cores are required, they are inserted prior to closing the mold. The shell mold is then placed into a flask and supported by a backing material.

4.Pouring - The mold is securely clamped together while the molten metal is poured from a ladle into the gating system and fills the mold cavity.

5.Cooling - After the mold has been filled, the molten metal is allowed to cool and solidify into the shape of the final casting.

6.Casting removal - After the molten metal has cooled, the mold can be broken and the casting removed. Trimming and cleaning processes are required to remove any excess metal from the feed system and any sand from the mold.

| Process | Shell Mold casting |

| Pattern | Steel mold |

| Mould Shell | Phenolic resin coated sand |

| Technology Characteristics | Suitable for mass production, and simple structure parts. |

| Tolerance Range | CT7 to CT8 |

| Single Weight | 0.2KGS to 50KGS |

| Surface Roughness | RA12.5 |

| Casting Material Type | Carbon Steel, Alloy Steel, Stainless Steel, Grey Iron and Ductile Iron |

| Common Material Specification | GB, ASTM,SAE,AISI,DIN,BS,JIS,NF,EN,AAR,ISO |

| Product application field | Automobile, Engineering Machinery, Railway, Marine, Agricultural Machinery, Mining and other industrial fields |

Water Glass Investment Casting

Water Glass Investment Casting

The difference between the lost wax method and water glass casting is simply the way the wax is removed from the ceramic mould:

· Investment casting uses high temperature autoclaves to melt the wax, whereas:-

· In Water glass casting the molds are submersed in hot water to remove the wax. The wax is then melted away from the molds and it floats on the surface of the water. This then allows for it to be skimmed off and reused for wax making purposes.

Obviously, this also provides environmental advantages and the wax is completely recyclable.

Lester-cast is able to offer the water glass option through its partner company in China, who have a wealth of experience in manufacturing components using this process.

To summarize, the water glass process offers:

· Superior surface finish than sand casting.

· Greater dimensional precision than sand casting.

· Achieve more complex parts.

· Larger parts than the traditional investment casting method.

· Cheaper than investment casting.

· Greater choice of metals.

· Environmental advantages.

Water glass casting is one of investment casting process, in which water glass is added into the molding materials in proportion and then gets stirred and mixed for 6-8 min, then grind into “ sodium silicate-bonded sand”. Then the sand is put into the mold boxes in which CO2 has been much blown into. CO2 starts the chemical reaction with the water glass to from the silica gel which hardens the sodium silicate-bonded sand.

Why choose water glass casting for your customized parts?

The water glass casting parts is the most cost-effective casting process with short shell making cycles, which helping you to cut a lot costs.

Compared with silica sol casting parts, water glass casting components is with large surface roughness and low dimension accuracy.

The surface quality of investment water glass casting parts is poor, so it is mainly used for carbon steel and low alloy steel castings. And the silica sol precision casting is mainly used for high-alloy steel and stainless steel products.

Application: China water glass castings is widely applied throughout all kinds machinery, such as automotive castings, engineering machinery casting, agricultural casting parts, motor casting components, elevator cast parts, mining parts, earth-moving machinery casting components, construction machinery casting parts, marine & ship casting, pump fittings, hydraulic cylinder castings, valve casting spare parts and various metal casting.

| Process | Water glass Casting |

| Mold | General Aluminum Mold & Steel Mold |

| Mold Material | Low Temperature Wax |

| Mold Shell | Sodium Silicate, Quartz Sand |

| Technology Characteristics | Suitable for complicated structures. Reduced machining allowance. Decrease production cost. |

| Tolerance Range | CT7 to CT9 |

| Single Weight | 0.5kgs to 200kgs |

| Surface Roughness | RA12.5 |

| Casting Material Type | Carbon Steel, Alloy Steel, Grey Iron and Ductile Iron |

| Common Material Specification | GB, ASTM,SAE,AISI,DIN,BS,JIS,NF,EN,AAR,ISO |

| Product application field | Automobile, Engineering Machinery, Railway, Marine, Agricultural Machinery, Mining and other industrial fields |

Featured Products

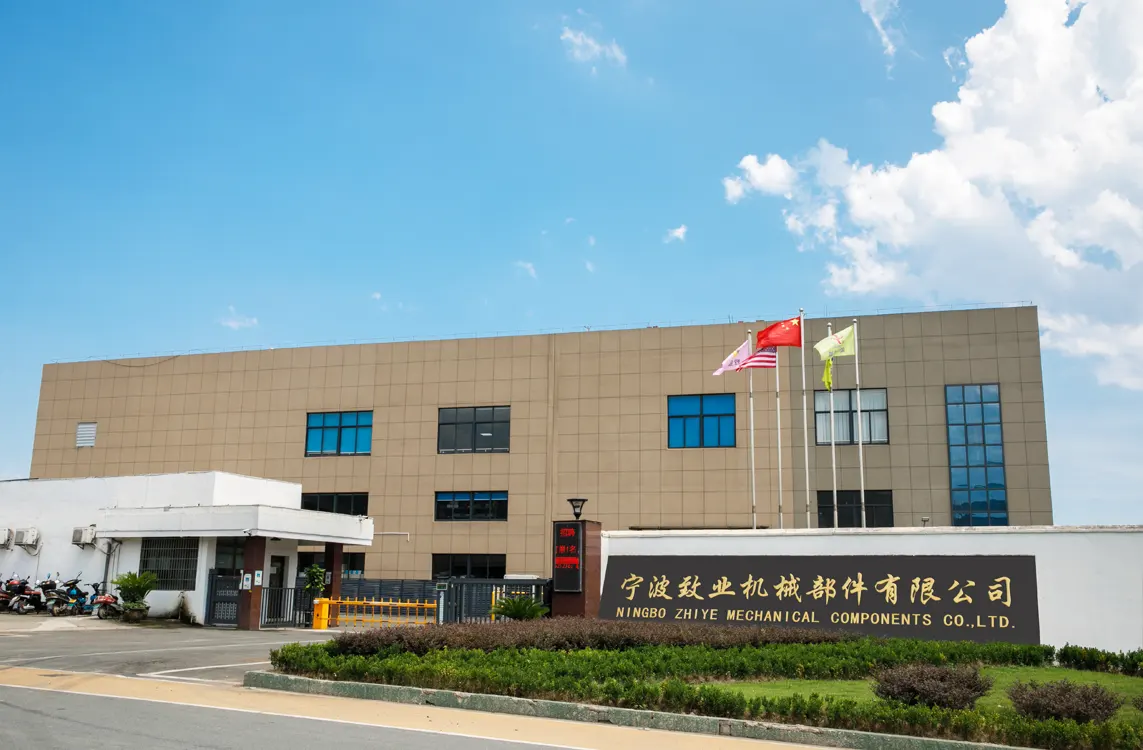

About Us

about

us

Ningbo Zhiye Mechanical Components Co.,Ltd.It is located at Xiachen Industrial Zone,Chunhu Town,Fenghua District,Ningbo City,which is known for its precision castings in China.It is subordinated to Ningbo Huashen Group,which have 5 companies in total.With over 900 employees and the annual production output is more than 3,000 tons.The main business ranges are Silica Sol Investment Casting, Water Glass Investment Casting, Lost Foam Casting, Shell Mold Casting and Composite Lost Wax Investment Casting.It has been a famous supply for precision castings in China.

OUR CUSTOMERS

-

General Motors

-

Bavarian Motor Work

-

Honda Motor

-

Build Your Dreams

-

Chrysler

-

Horizon

-

Paladin

-

GMS

-

Paragon

-

BYG

-

BLACKWOOD ENGINEERING

-

Caterpillar

-

Material choose

Material choose

According to the customer's requirements, we will choose the most suitable materials by research & development to reduce the cost of product.

View Details -

Software skills

Software skills

We master a variety of design software tools (CAD, PRO/E, Solid Work), Simulation Software (Any casting), Measurement Software (CALYPSO, OBLF), laying the foundation for professional services for customers.

View Details -

Weight reduction

Weight reduction

We can provide customers suggestions and design solutions for lightweight products.

View Details -

Actual sample survey

Actual sample survey

We can develop samples by surveying and drawing on the actual samples provided by customers.

View Details -

Structure transform

Structure transform

We can provide customers structure transforming on stamping parts, welding parts to castings which will improve the service life of the product and reduce the product cost.

View Details -

Patent

Patent

We have our own patented designs.

View Details

New Products

News

What are the performance characteristics of precision castings?

The maximum length of precision castings is 700mm, the easy-to-make length is less than 200mm, and the maximum weight is about 100kg, usually less than 10kg.

Why is lost foam casting expensive?

Lost foam casting, also known as evaporative pattern casting, is a complex and specialized casting process that involves creating a foam pattern of the desired metal part, coating it with refractory material, and then pouring molten metal into the mold. While it offers several advantages, such as intricate shapes and fine details, there are several reasons why lost foam casting can be relatively expensive:

When to Use Investment Casting In Automotive

Investment casting is a versatile manufacturing process that can be used in various applications within the automotive industry. It offers several advantages that make it suitable for specific components and scenarios. Here are some situations where investment casting is commonly used in the automotive sector:

Comparison of Stainless Steel and Aluminum in Investment Casting

Stainless steel and aluminum are both commonly used materials in investment casting, which is a precision manufacturing process that involves creating complex shapes by pouring molten metal into a ceramic mold. Each material has its own set of advantages and limitations in investment casting. Here's a comparison between stainless steel and aluminum in investment casting:

Solutions to improve innovative ability of investment casting talents

Currently,technology is still the biggest problem of investment casting industry in our country.Although we are always winning good reputation from overseas investment casting specialists,there are still some bad influence for the lack of technology.So if we want to enlarge investment casting market,we must improve talents' innovative ability.

Investment casting mould industry

With the development of the domestic investment casting industry and mold industry,related equipments like vertical and gantry machining center, CNC lathe are also get fast developed,which greatly improve the precision and depth of investment casting industry.